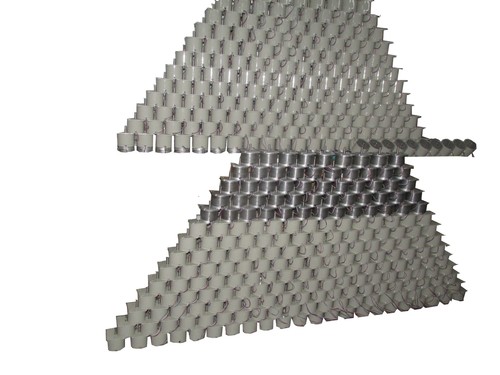

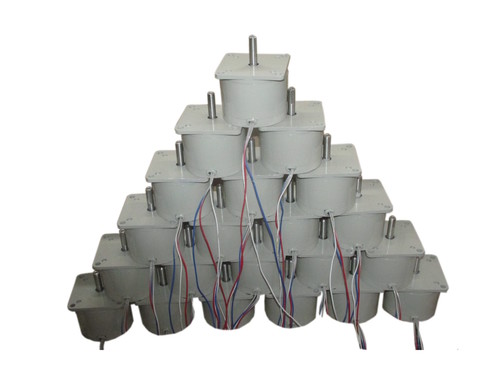

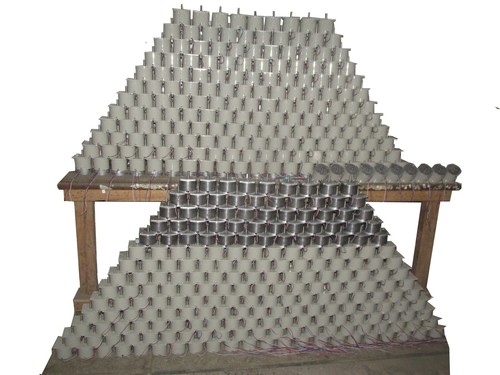

AC Servo Motors

Price 1 INR/ Piece

AC Servo Motors Specification

- Voltage

- 220 V / 380 V

- Bearing Type

- Ball Bearing

- Rated Voltage

- 220 V / 380 V

- Noise Level

- Low Noise

- Horse Power

- 0.27 HP to 10 HP

- Rated Frequency

- 50 Hz / 60 Hz

- Power Rating

- 0.2 kW to 7.5 kW

- Torque

- High Starting Torque

- Starting Type

- Direct On Line (DOL)

- Cooling Method

- Fan Cooled (TEFC)

- Current Type

- AC

- Standard

- IEC/IS Standard

- Motor Type

- AC Servo Motor

- Pressure

- Atmospheric

- Ambient Temperature

- -10C ~ 40C

- Sealed Type

- Totally Enclosed

- Poles Number

- 2, 4, 6, 8 Poles

- Features

- Precise Control, Low Maintenance, High Response

- Efficacy

- High Efficiency

- Product Type

- Asynchronous Motor

- Output Power

- 200 W to 7.5 kW

- Frequency (MHz)

- 50 Hz / 60 Hz

- Protect Feature

- Overload, Phase Loss, Overcurrent

- Phase

- Single Phase / Three Phase

- Speed

- Up to 3000 RPM

- Power

- 200 W - 7.5 kW

- Color

- Black and Silver

- Dimension (L*W*H)

- Various Models (customizable)

- Weight

- Depends on Model

- Shaft Diameter

- As per Model Specification

- Mounting Type

- Foot / Flange Mount

- IP Rating

- IP55

- Enclosure

- Aluminum Die-cast

- Control Method

- PWM Frequency Control

- Life Expectancy

- >20,000 Hours

- Vibration Level

- 2.8 mm/s

- Compliance

- CE, RoHS Certified

- Application

- CNC Machines, Automation, Robotics, Packaging Machinery

- Braking Option

- Optional (Electromagnetic Brake)

- Service Factor

- 1.0 to 1.15

- Connection

- Terminal Box / Lead Wires

- Relative Humidity

- <85% (non-condensing)

- Feedback Device

- Incremental / Absolute Encoder

- Frame Size

- 56 mm to 180 mm

- Insulation Class

- F / H

AC Servo Motors Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 1 Unit Per Day

- Delivery Time

- 1 Week

- Sample Available

- Yes

- Main Domestic Market

- All India

About AC Servo Motors

Optimized for Precision Applications

These AC Servo Motors are tailored for industries requiring high responsiveness and accuracy, making them ideal for CNC machines, advanced robotics, and automation systems. Their high starting torque and precise position control ensure seamless and reliable integration into complex manufacturing processes.

Robust Design and Flexible Installation

Constructed with an aluminum die-cast enclosure and IP55 sealing, the motors offer superior resistance to dust and moisture. Flexible mounting options such as foot or flange mount accommodate varying installation requirements. The low-noise and fan-cooled design make them suitable for noise-sensitive environments.

Advanced Features for Maximum Efficiency

The motors incorporate overload, phase loss, and overcurrent protection, increasing operation safety and reliability. They support direct-on-line (DOL) starting and feature electromagnetic brake options for enhanced control. Compliance with CE and RoHS standards ensures safe, environmentally-friendly operation.

FAQs of AC Servo Motors:

Q: How do AC Servo Motors enhance precision in CNC machines and robotics?

A: AC Servo Motors deliver precise control due to their high starting torque, rapid response, and the inclusion of incremental or absolute encoders for accurate feedback. This allows for exact positioning critical in CNC machines, automation systems, and robotics, ensuring optimal performance and repeatability.Q: What are the typical applications of these AC Servo Motors?

A: These motors are commonly used in CNC machinery, automation setups, robotics, and packaging equipment. Their ability to operate with a variety of feedback devices and mounting options makes them adaptable for industries demanding high precision and reliability.Q: When should I consider using the braking option in these servo motors?

A: The electromagnetic brake option is recommended for applications where the machinery needs to maintain a fixed position when powered down or where safety is a concern, such as vertical axes in robotics or packaging equipment handling heavy loads.Q: Where can these AC Servo Motors be installed, and what environmental conditions do they support?

A: Designed for industrial environments, these motors can be installed in locations with ambient temperatures from -10C to 40C and relative humidity below 85%. Their IP55-rated, fully enclosed aluminum housing makes them suitable for areas exposed to moderate dust and moisture.Q: What is the process for selecting the right model for a specific application?

A: Selection should consider frame size, output power, required mounting style (foot or flange), voltage and phase compatibility, feedback device preference, and any optional features such as electromagnetic brakes. Consult the model specification to match shaft diameter, weight, and exact dimension needs.Q: How does PWM frequency control benefit motor operation?

A: PWM frequency control allows for smoother and more efficient speed regulation, reduce losses, and accurate adjustment of motor output. This ensures the motor operates efficiently across a range of speeds, which is vital for high-precision industrial applications.Q: What are the primary benefits of using these AC Servo Motors from an operational perspective?

A: Key advantages include high efficiency, low operational noise, extended life expectancy, robust protection features, and minimal maintenance requirements. These benefits contribute to lower downtime, reduced operational costs, and sustained high performance in dynamic industrial environments.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in AC Synchronous Motors Category

Permanent Magnet AC Synchronous Motors

Price 1 INR / Piece

Minimum Order Quantity : 1 Unit

Sealed Type : Other, IP55

Phase : Three Phase

Mounting Type : Foot Mounted

Dimension (L*W*H) : 280 x 190 x 220 mm

AC Synchronous Motors

Price 1 INR / Piece

Minimum Order Quantity : 1 Unit

Sealed Type : Other, Closed

Phase : Single Phase

Mounting Type : Flange / Foot

Dimension (L*W*H) : Customized

Servo Voltage Stabilizer Motor

Price 1 INR / Piece

Minimum Order Quantity : 1 Unit

Sealed Type : Other, Totally Enclosed Fan Cooled (TEFC)

Phase : Single Phase

Mounting Type : Foot Mounted

Dimension (L*W*H) : 250mm x 120mm x 180mm

Industrial AC Servo Motors

Price 1 INR / Piece

Minimum Order Quantity : 1 Unit

Sealed Type : Other, IP65

Phase : Three Phase

Mounting Type : Flange Mount

Dimension (L*W*H) : Depends on model

GST : 07ADFPN1525M2ZF

|

NARULA ELECTRICALS

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry