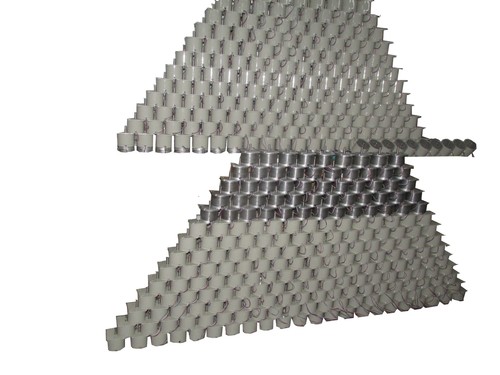

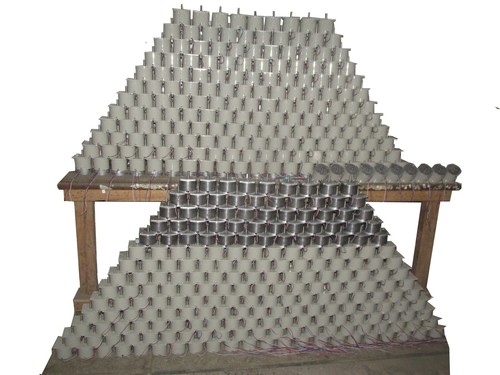

AC Synchronous Motors

Price 1 INR/ Piece

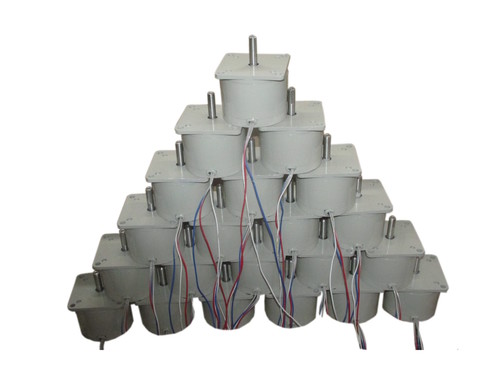

AC Synchronous Motors Specification

- Horse Power

- 0.06~0.5 HP

- Pressure

- Normal

- Features

- Long life, High efficiency, Stable performance, Low noise

- Bearing Type

- Ball Bearing

- Ambient Temperature

- -20C to +50C

- Rated Voltage

- 110/220 V

- Torque

- 10~60 Nm

- Poles Number

- 2/4/6

- Rated Frequency

- 50/60 Hz

- Cooling Method

- Self-Cooled

- Standard

- IEC, CE

- Starting Type

- Direct-On-Line

- Sealed Type

- Closed

- Current Type

- AC

- Noise Level

- 45 dB

- Power Rating

- 4-40 W

- Motor Type

- AC Synchronous Motor

- Efficacy

- IE2

- Voltage

- 110/220 V

- Product Type

- Asynchronous Motor

- Output Power

- 4-40 W

- Frequency (MHz)

- 50/60 Hz

- Protect Feature

- Totally Enclosed

- Phase

- Single Phase

- Speed

- 5~1500 RPM

- Power

- 4-40 W

- Color

- Silver / Black

- Dimension (L*W*H)

- Customized

- Weight

- 0.5~5 kg

- Shaft Diameter

- 6~16 mm

- Mounting Type

- Flange / Foot

- IP Rating

- ip44

- Vibration Level

- 2.5 mm/s

- Adjustable Speed

- Available

- Service Factor

- 1.0

- Ambient Humidity

- 90% RH

- Insulation Class

- Class B/F

- Rotor Type

- Salient Pole

- Application

- Automation, Industrial Equipment, Pumps

- Product Type (As per user)

- Asynchronous Motor

- Enclosure

- Totally Enclosed Fan Cooled (TEFC)

- Duty

- S1 (Continuous)

AC Synchronous Motors Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 1 Unit Per Day

- Delivery Time

- 1 Week

- Sample Available

- Yes

- Main Domestic Market

- All India

About AC Synchronous Motors

Electric Servo Motors

Established in the year 1989, we have created our name as a well-renowned manufacturer and supplier of both AC an DC Electric Servo Motors in the global market. These small sized motors are highly appreciated for their excellent working efficiency, optimum performance, ability to withstand high pressure and corrosion resistance. Offered motors are widely demanded for several industrial and commercial applications such as in-line manufacturing, radio controlled airplanes, elevators, rudders, robots and so-forth. Apart, these motors now considered as an best alternative to ac induction motor. We offer these Electric Servo Motors to our respectable clients at the market leading prices.

Features:

- Highly energy efficient

- Compact in size

- Less power consumption

- Easy and safe to use

- In-built servo circuitry

- Precise regulation

Advanced Protection and Efficiency

Equipped with a totally enclosed construction and TEFC enclosure, these motors offer optimal protection against dust and moisture, making them ideal for industrial environments with high humidity. With IE2 efficiency, they achieve lower energy consumption and heat generation, ensuring long-lasting performance and operational reliability even at continuous duty cycles.

Customizable Solutions for Industry Needs

Shaft diameter, dimensions, mounting type, and color can be customized to suit specific installation requirements. These motors are available with flange or foot mounting and support both black and silver color options, making integration flexible for diverse industrial applications such as automation systems and pump assemblies.

FAQs of AC Synchronous Motors:

Q: How are AC Synchronous Motors with salient pole rotors suitable for industrial automation?

A: Their stable speed control, adjustable from 5 to 1500 RPM, and robust design with TEFC enclosure support continuous, reliable operation required in automation systems, handling high humidity and sustained duty cycles without performance degradation.Q: What is the process for customizing the mounting type, dimensions, or shaft diameter?

A: Customers can specify mounting type (flange or foot), shaft diameter (616 mm), and dimensions during ordering. The manufacturer coordinates these requirements, ensuring the motor is tailored to fit specific equipment or installation constraints.Q: When should I consider using motors with insulation Class B or F?

A: Class B or F insulation provides enhanced resistance to heat and moisture. These are recommended for environments where continuous operation or exposure to high ambient temperature and humidity could affect motor life, such as in industrial and automated systems.Q: Where can these motors be installed considering their IP44 and TEFC features?

A: They can be installed indoors in industrial settings or areas with moderate exposure to dust and moisture. The IP44 rating and TEFC enclosure protect internal components from environmental hazards, making them suitable for automation lines, pump rooms, and general industrial zones.Q: What benefits does the synchronous design offer over asynchronous types for continuous operation?

A: Synchronous motors maintain a constant speed irrespective of load changes and offer better speed regulation compared to asynchronous variants, making them ideal for processes requiring precise motion control over extended periods.Q: How does the adjustable speed feature enhance usage in pump applications?

A: Adjustable speed allows users to match motor output precisely to process requirements, improving energy efficiency and reducing mechanical stress in pumps. It supports a wide range from low to high RPM, adapting to varying fluid movement needs.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in AC Synchronous Motors Category

Servo Voltage Stabilizer Motor

Price 1 INR / Piece

Minimum Order Quantity : 1 Unit

Starting Type : Direct OnLine

Dimension (L*W*H) : 250mm x 120mm x 180mm

Color : Grey

Current Type : AC

Permanent Magnet AC Synchronous Motors

Price 1 INR / Piece

Minimum Order Quantity : 1 Unit

Starting Type : Direct OnLine

Dimension (L*W*H) : 280 x 190 x 220 mm

Color : Blue

Current Type : AC

AC Servo Motors

Price 1 INR / Piece

Minimum Order Quantity : 1 Unit

Starting Type : Direct On Line (DOL)

Dimension (L*W*H) : Various Models (customizable)

Color : Black and Silver

Current Type : AC

Industrial AC Servo Motors

Price 1 INR / Piece

Minimum Order Quantity : 1 Unit

Starting Type : DirectOnLine

Dimension (L*W*H) : Depends on model

Color : Black / Silver

Current Type : AC

GST : 07ADFPN1525M2ZF

|

NARULA ELECTRICALS

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry